瓦楞成形机 RWJ150-1800 Features: Maximum production width: 1800 mm (Other sizes available upon request), Hydraulic shaftless mill roll stands with pneumatic brakes, Glue making station, Heating method: Steam, Flute-type: A C B E F N or any combination, Duplex pre-heater (optional), Fingerless type facer, Double facer with heating plates and cooling section, Corrugated paper: 100 - 150g/m2, Maximum Speed: 150m/min, Conveyor bridge (optional), Core paper: 100 - 250g/m2, Computarized stacker with batch counting, Computerized gantry with right or left angle stacking, Multi-cassette positive pressure single facer (optional), NC thin knife cutter with helical knives (optional), Paper moisture content of about: 11% +/- 2%, Paper rating of not less than a B grade quality material, Steam boiler capacity: 2.5 to 5.5 Tons/Hr depending on the configuration, Steam management system, Steam temperature range: 160-200 Celsius, Thin knife slitting unit (optional), Three-layer corrugated cardboard production line, Top and bottom paper preheating cylinder, Top paper: 100 - 250g/m2, Specifications are subject to change without notice.

瓦楞成形机 RSF-D-280 Features: Working width: 1200-2000 mm, Pressured Roller Diameter: 284mm/45# Steel, Preheating Roller Diameter: 405mm/45# Steel, Maximum Speed: 120 m/min, Glue Roller Diameter: 215mm/45# Steel, Fingerless type facer, Top paper: 100 - 250g/m2, Wall Thickness: 130mm/HT200 Casting, Steam temperature range: 160-200 Celsius, Steam Consumption: 0.5-0.8 Tons/Hour, Two-layer corrugated cardboard production line, Heating method: Steam, Specifications are subject to change without notice, Top and bottom paper preheating cylinder, Thin knife slitting unit (optional), Steam management system, Preheating Roller Diameter: 900mm/45# Steel, Paper rating of not less than a B grade quality material, Paper moisture content of about: 11% +/- 2%, Mean Production Speed: 80 m/min, NC thin knife cutter with helical knives (optional), Hydraulic shaftless mill roll stands with pneumatic brakes, Corrugated Roller Diameter: 280mm/48CrMo Steel, Corrugated paper: 100 - 150g/m2, Core paper: 100 - 250g/m2, Conveyor bridge (optional), Computarized stacker with batch counting, Available Flute-types: A C B E F N, Steam pressure: 1.2Mpa, Multi-cassette positive pressure single facer (optional), Duplex pre-heater (optional), Hydraulic roll stand.

奥润托机械是全球最具经验的供应商之一,主营来自世界各地的新旧印刷机,印后加工机械,包装机械,纸箱加工设备。在过去的72年里,我们销售了非常多新旧印刷机和印后加工设备给加勒比海地区,拉丁美洲的印刷厂。我们对地区和熟悉和与客人的特殊关系让我们比同行更具竞争力。

罗佑家族和它的亚洲销售团队积累了丰富的运输经验,也具备采购和销售包装,纸箱,印后加工设备的技术知识,同时我们能提供给您其他的附加服务:采购前检验机械,拆分,移除,清洗,喷油,重组,改装设备和零件,运输,安装调试,售后服务,保修,评估和专业的咨询。

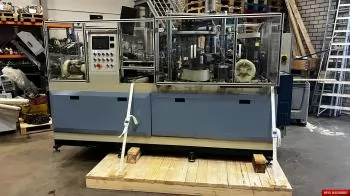

从1948年至今,我们组建了完善的网络团队为您在全球寻找价格合理且优质的新旧印刷设备,印后设备,包装,纸箱设备,我们能为您提供模切机,糊盒机,UV腹膜机,纸卷切片机,纸杯机,或者其他任何您想要的设备。