Corrugator RWJ150-1800 Features: Maximum production width: 1800 mm (Other sizes available upon request), Hydraulic shaftless mill roll stands with pneumatic brakes, Glue making station, Heating method: Steam, Flute-type: A C B E F N or any combination, Duplex pre-heater (optional), Fingerless type facer, Double facer with heating plates and cooling section, Corrugated paper: 100 - 150g/m2, Maximum Speed: 150m/min, Conveyor bridge (optional), Core paper: 100 - 250g/m2, Computarized stacker with batch counting, Computerized gantry with right or left angle stacking, Multi-cassette positive pressure single facer (optional), NC thin knife cutter with helical knives (optional), Paper moisture content of about: 11% +/- 2%, Paper rating of not less than a B grade quality material, Steam boiler capacity: 2.5 to 5.5 Tons/Hr depending on the configuration, Steam management system, Steam temperature range: 160-200 Celsius, Thin knife slitting unit (optional), Three-layer corrugated cardboard production line, Top and bottom paper preheating cylinder, Top paper: 100 - 250g/m2, Specifications are subject to change without notice.

Corrugator RSF-D-280 Features: Working width: 1200-2000 mm, Pressured Roller Diameter: 284mm/45# Steel, Preheating Roller Diameter: 405mm/45# Steel, Maximum Speed: 120 m/min, Glue Roller Diameter: 215mm/45# Steel, Fingerless type facer, Top paper: 100 - 250g/m2, Wall Thickness: 130mm/HT200 Casting, Steam temperature range: 160-200 Celsius, Steam Consumption: 0.5-0.8 Tons/Hour, Two-layer corrugated cardboard production line, Heating method: Steam, Specifications are subject to change without notice, Top and bottom paper preheating cylinder, Thin knife slitting unit (optional), Steam management system, Preheating Roller Diameter: 900mm/45# Steel, Paper rating of not less than a B grade quality material, Paper moisture content of about: 11% +/- 2%, Mean Production Speed: 80 m/min, NC thin knife cutter with helical knives (optional), Hydraulic shaftless mill roll stands with pneumatic brakes, Corrugated Roller Diameter: 280mm/48CrMo Steel, Corrugated paper: 100 - 150g/m2, Core paper: 100 - 250g/m2, Conveyor bridge (optional), Computarized stacker with batch counting, Available Flute-types: A C B E F N, Steam pressure: 1.2Mpa, Multi-cassette positive pressure single facer (optional), Duplex pre-heater (optional), Hydraulic roll stand.

Oriental Machinery is one of the world's most experienced suppliers of new and used printing, finishing and carton converting equipment worldwide. We have sold more new and used printing and finishing equipment to the Caribbean and Latin American printers than any other company over the last 72 years. Our exceptional relationship and understanding of the region gives our company a competitive edge over competitors.

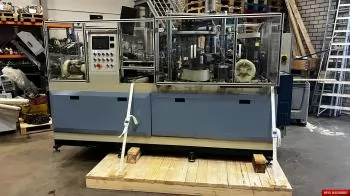

The Royo Family and its Asian team have accumulated the expertise to help you with the logistics and the engineering required to manage the process of buying and selling packaging, carton and converting machinery from Asia anywhere in the world. We offer additional services such as pre-purchase inspections, dismantling and removal, parts, cleaning and painting, rebuilding and retrofitting, transportation, installation and demonstration, after sales service and warranty, appraisals and professional consultation.

Being in the industry since 1948 has allowed us to build a global network dedicated to finding the new or used printing, finishing and packaging and carton converting equipment you might be looking for at the most competitive prices. Let us help you find the Die Cutter, Box Folder Gluer, UV Coater, RollSheeter, Paper Cup Making Machine or any other machine you are looking for.